MA GRADE ABRASIVES

Best choice for optima grinding applications!

With development of grinding applications, conventional abrasives lost their advantage in some fields due to lower grinding efficiency.

By adoption latest technology, Hunan Cutall Superabrasives Co., Ltd. developed a new type of material-MA grade abrasives for those applications where longer tools life and higher cutting rate are required. With stronger hardness, the material can be used grinding various materials such as steel parts of textiles machine, ceramic tiles.

Compared to conventional abrasives like silicone carbide and

aluminum oxide, MA material has some unmatched advantage:

⊙ Increased parts per hour / cycle time reduction

⊙ Labor cost saving

⊙ Less tool changes

⊙ Reduced scrap rate

⊙ Reduced machine maintenance

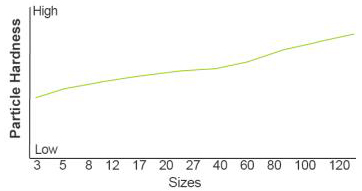

Relative Particle Hardness |

Composition of Products |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Sizes Availability

All our MA grade abrasives are sieved under controlled conditions in accordance with international standard. The products are available as standard in the full range size from 3-120.

Sizes can be supplied:

MA-3, MA-4, MA-5, MA-6, MA-7, MA-8, MA-10, MA-12, MA-14, MA-17, MA-20, MA-23

MA-27, MA-32, MA-40, MA-50, MA-60, MA-70, MA-80, MA-90, MA-100, MA-110, MA-120